The production of both tableware and art ceramics involves similar techniques, such as shaping clay, applying glazes, and firing in kilns.

The final firing temperatures can vary significantly depending on the type of clay, shapes, and glaze used, but they generally range from 2100°F to 2400°F (1150°C to 1300°C).

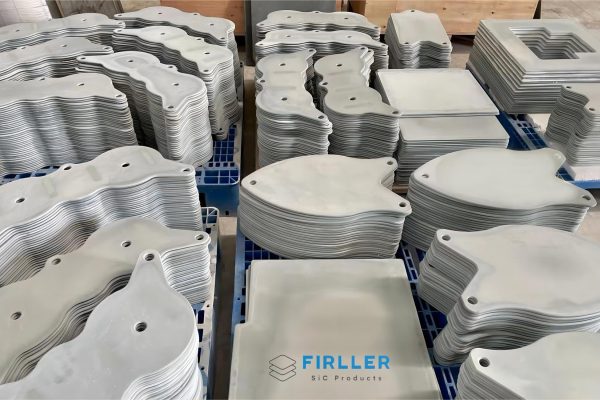

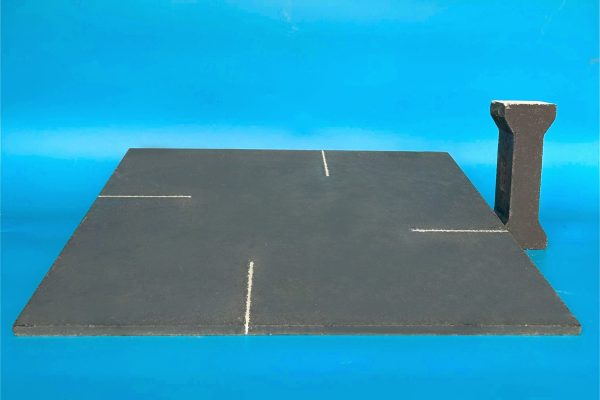

Proper arrangement of pieces on kiln furniture ensures even firing, preventing warping or breakage. This is particularly important for tableware and art ceramics, where maintaining the desired form and texture is crucial.